If you have ever watched a windshield get replaced, it can look deceptively simple. Out comes the cracked glass, in goes the fresh pane, a bead of black sealant around the frame, and the technician says you are good after a short wait. What most people never see is the quiet star of the entire job: the adhesive. That glossy bead is more than glue. It is structural, safety-critical, and picky about how it is used. The difference between a rock-solid repair and a problem waiting to happen often comes down to chemistry, technique, and the patience to follow every step.

I have stood in cold garages at dawn with a curing lamp humming, watched urethane set under desert heat, and learned the temperament of primers that turn hazy if you rush them. The windshield is now a load-bearing part of most vehicles. During a collision or rollover, it helps keep the roof from caving in and ensures airbags deploy correctly. None of that is reliable if the glass does not bond to the body the way the engineers intended. So, when we talk about auto glass replacement, we are really talking about three intertwined elements: a proper-fitting windshield, clean and prepared surfaces, and a high-quality adhesive system applied with discipline.

What the Windshield Actually Does

Drivers often think of the windshield as a shield against wind, rain, and pothole flung gravel. It is all that, but modern vehicles lean on it structurally. Automakers design front airbags to deflect off the windshield and back toward occupants. If the bond fails and the glass separates, that airbag can blow through the opening or misdirect, and its protective timing gets compromised. In a rollover, the windshield helps keep the roof from collapsing. You will see it in crash-tests: when the glass stays bonded, the cabin stays stiffer.

The windshield also contributes to body rigidity in normal driving. A well-bonded windshield quiets squeaks, reduces flexing over driveway lips, and keeps the dashboard from blooming with rattles. If you have had a replacement and later noticed a whisper of wind at highway speed or a faint tick over bumps, that usually points to a compromised seal, an uneven bead, or contamination that kept the adhesive from fully wetting the surface.

The Role of Adhesives in Auto Glass Repair

In the world of auto glass repair, adhesive technology has evolved to match higher safety standards and faster service expectations. Early butyl tapes gave way to moisture-curing polyurethane urethanes, which brought strong bonds, flexibility, and durability. Today, most professional auto glass replacement jobs use an OEM-approved polyurethane adhesive system that includes cleaners, activators, and primers matched to the glass and the vehicle’s painted pinchweld.

When a quick windshield chip repair can save a windshield, resin injection takes the lead. That is a different chemistry and objective, filling microfractures to keep them from spreading. But once a crack reaches the edge or grows across the driver’s line of sight, the talk shifts to replacing the glass and building a safe bond between glass and steel. That bond is where the quality of your adhesive matters.

Why “Any Urethane” Is Not Good Enough

Two urethanes can look the same as they sit on a shelf, yet behave very differently on a car. Some formulas cure faster, some hold better in high heat, some resist UV degradation. Others are tailored for high modulus performance to add stiffness. Cheaper urethanes might be fine for a side glass repair on a farm truck that spends its life under 45 mph. They are not fine for a modern SUV that relies on the windshield to calibrate cameras and support advanced driver assistance systems.

Beyond the formula, there is compatibility. Not every primer plays nicely with every urethane. A mismatched system can weaken bond strength by 20 to 40 percent. I have seen pull tests where a properly chosen urethane ripped a rubber encapsulation before the bond failed, while an off-brand product peeled clean like tape from dusty drywall. On paper, both claimed similar tensile strengths. In practice, only one did what the vehicle engineering assumed it would.

Surface Prep: The Part No One Sees, and Everyone Feels

You cannot build a strong bond on a dirty surface. Road film, silicone from car-care products, body shop overspray, human skin oils, even pollen, can sabotage adhesion. Every professional job should start with cleaning. That usually means a dedicated glass cleaner or an alcohol-based wipe, followed by gloves that stay on until the job is done. From there, technicians remove the old urethane but leave a specific thickness behind, often about a millimeter or two of the original bead, called the full-cut method. Fresh urethane bonds beautifully to that layer as long as it is sound and not oxidized.

Primer selection comes next. Glass primer activates the frit band on the windshield, that dotted black ceramic edge you see around the perimeter. It helps the adhesive bite into the glass and adds UV protection. Pinchweld primer treats any bare metal where paint might have lifted during removal, providing corrosion resistance and a chemically active surface. Skipping primer, or applying too much, can lead to trouble. A heavy coat can pool and release solvents into the urethane bead, leaving it soft or swollen at the edges. Too little primer on a scuffed spot of metal can invite rust months later, which lifts the bond like a blister under paint.

Clock Time: Safe Drive-Away Is Not a Guess

Most drivers want to leave as soon as the new windshield is in. That is understandable. But safe drive-away time is not a coin flip or a “feels dry” touch test. It is a function of adhesive type, temperature, humidity, and the number of airbags tied into the windshield area. Many one-part urethanes reach minimal crashworthy strength within 30 to 90 minutes under standard conditions. Standard, in this case, usually means 70 degrees Fahrenheit and 50 percent relative humidity. Colder, drier weather slows the cure. A respected 30-minute urethane can take two hours to reach the same strength on a 40-degree morning with low humidity. If your installer lets you go too soon, the bond might not hold in a sudden stop or an airbag event.

Quality adhesives publish tested safe drive-away charts and have batch numbers you can trace. When I see a technician check the thermometer and glance at the hygrometer clipped to their tool bag, I know I am dealing with someone who will not cut corners on time.

Heat, Cold, and the Real World

Adhesives are sensitive to climate. In Phoenix heat, the bead becomes more pliable during application and may skin quickly, demanding steady hands and a fast set of maneuvers to place the windshield without strings or voids. In Minneapolis winters, everything slows. A heater blowing across the dash helps, and some shops run portable curing lamps. You can, in a pinch, warm the urethane sausage in a water bath or with a dedicated warmer to make it extrude more evenly. What you should not do is place a cold windshield onto a hot bead or vice versa, which can build stress and microgaps.

I learned this the hard way years ago on a pickup with a fresh coat of paint. The shop had heated the interior to fight the snow outside. The glass came from an unheated rack. Within a day, the customer heard a faint tick along the passenger side. We pulled it and found tiny gaps where the bead had skinned before the glass fully seated. The fix was tedious, but it taught a lasting lesson: match temperatures, control the environment, and do not rush the cure.

The Chemistry Behind the Bead

Polyurethane urethanes cure through moisture in the air and on the surface. The polymer crosslinks to form a strong, elastic bond, which is part of why the windshield can flex with the body and still hold. Some high-performance lines add silane-modified technology for better adhesion to a range of substrates or improved green strength. You might also see two-part urethanes that cure by chemical reaction rather than ambient moisture. Those can deliver fast, predictable cures in a wider range of conditions, but they require mixing accuracy and specialized equipment. Most mobile jobs rely on one-part moisture-curing urethanes with carefully matched primers.

A common mistake is using household cleaners or glass treatments that leave hydrophobic films. Those films repel water and, unfortunately, also repel certain adhesive chemistries. If you recently had your windshield coated with a rain-repellent product, let your installer know. A good tech will clean past the frit band and use the correct activator to ensure a sound bond.

Structural Integrity and Airbag Timing

It is easy to focus on leaks and wind noise, because those are the symptoms you notice. Adhesive quality also affects deeper safety systems. The driver-side airbag often deploys toward the windshield and then bounces back toward you. That timing depends on the glass staying where it is. A bond that shears under pressure lets the glass move outward, changing the airbag’s path. Automakers run crash tests assuming specific adhesive performance. That is why OEMs specify urethane standards and why top-tier aftermarket adhesives aim to meet or exceed those standards.

A compromised bond can also influence how your vehicle handles vibrations. Cars can feel inexplicably “loose” after a low-quality auto glass replacement, especially over uneven pavement or in crosswinds. If the adhesive lacks the right modulus, the windshield will not contribute as much to the front structure. The result is subtle but noticeable to anyone who knows how the car felt before.

ADAS Cameras, Rain Sensors, and the Hidden Penalties of Poor Adhesion

Many windshields now hold cameras, sensors, and mounting hardware for advanced driver assistance systems. Lane keeping, automatic emergency braking, adaptive cruise control, and rain sensing rely on a stable, precise glass position. If the adhesive bead is uneven or too thin at a corner, the glass can sit twisted by a couple of millimeters. The car might still calibrate, but the camera’s reference can drift with temperature cycles as the glass moves, which makes your ADAS less reliable. I have seen cars pass a static calibration one day and drift out the next after a hot afternoon on the freeway baked stress into the bead.

Quality adhesives that maintain shape during cure and resist creep at temperature help keep that glass exactly where the camera expects it. Combine that with a correct bead height and the result is fewer mysterious calibration failures and less need for rework.

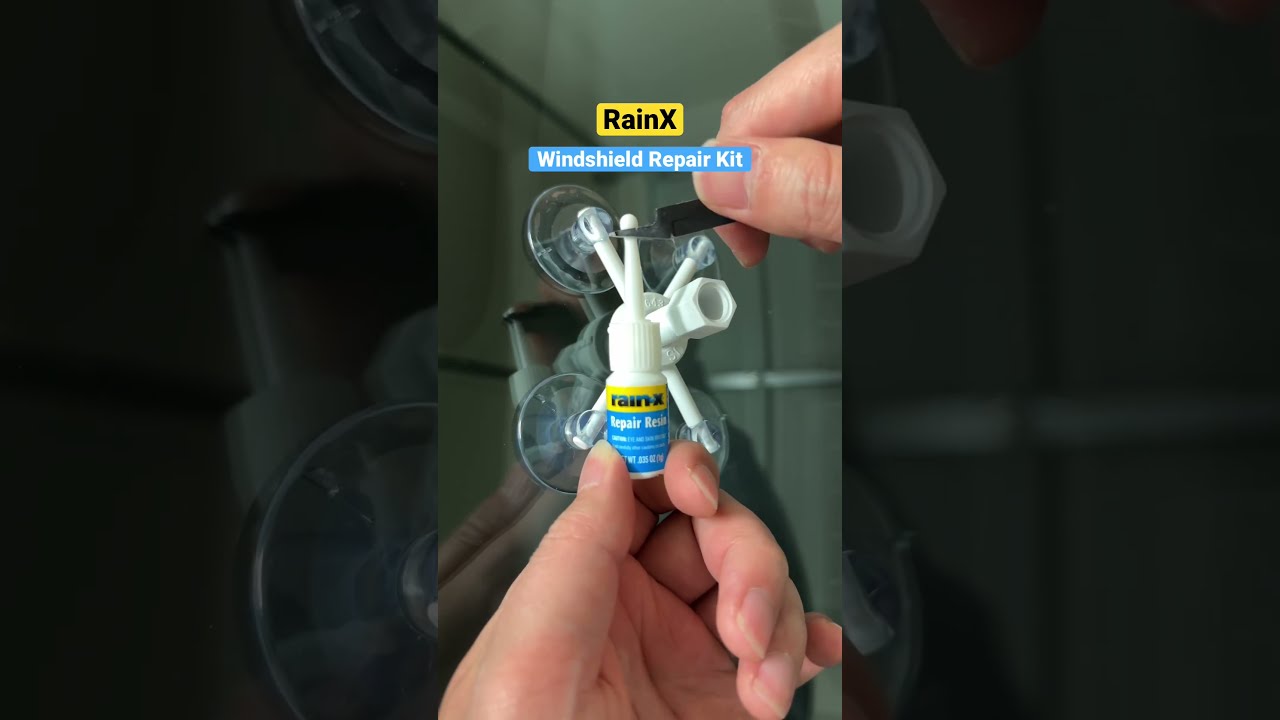

When Windshield Chip Repair Is Enough, and When It Is Not

Windshield chip repair and auto glass replacement are cousins, not twins. A small star break or bull’s-eye chip can often be stabilized with resin injection in less than half an hour, preserving the factory seal. It is cost effective and keeps the original bond intact. The trick is to act early. Once a crack reaches the edge or passes through the driver’s primary viewing area, replacement is generally the safer route.

I have repaired thousands of chips, and I still favor repair when it is appropriate. You keep the factory glass, you avoid disrupting the painted pinchweld, and you maintain the original modulus of the body. But when a replacement is necessary, the adhesive system becomes the backbone of the job. That is when a cheap product becomes false economy.

The Price Question: Where the Money Goes

People often ask why one shop charges meaningfully more for a windshield replacement than another. Some of that is glass quality and whether the shop uses OEM or high-grade aftermarket glass. A big chunk is the adhesive system and the time to apply it correctly. Premium urethane kits, matched primers, and activators can cost several times more than bargain options. Add in technician training, controlled cure times, and proper ADAS calibration, and the price difference starts to make sense.

If you see a surprisingly low quote that promises a fast in-and-out service regardless of weather, ask what adhesive they use, what the safe drive-away time is for your specific conditions, and whether they will document the batch numbers. A reputable installer will have straightforward answers.

The Things Pros Watch That You Might Not Notice

Every good auto glass repair tech develops habits that serve as guardrails. Gloves on, fresh nozzles for clean bead geometry, consistent bead height, and a quick visual after set to ensure the glass has a uniform reveal. We check pinch welds for rust and clean beyond the obvious edges. We shake primers, then dispense a bit onto a towel to confirm the color and consistency before we touch the vehicle. We avoid touching the frit after priming, and we time the window between primer flash-off and bead application. We also align the windshield using dowels or set blocks to ensure the bead is compressed evenly.

One small move that prevents headaches: taping and sealing the cowl so washer fluid or degreaser cannot wick into the bond area during or after the job. Contaminants often sneak in from the bottom, not the top.

Real-World Failure Modes

Failures rarely announce themselves on day one. Problems emerge slowly.

- A faint whistle at speed that grows over weeks points to a void in the bead or glass that settled as the urethane cured. Wind pushes at that weak spot until the gap opens. Left alone, water finds it next. A smell of mildew after rain often traces to a leak at the lower corners where the bead was thin. Water creeps, wicks, and soaks the carpet padding long before you notice it. By the time the smell arrives, the cleanup is expensive. A crack reappearing from the same area following a minor fender-bender can indicate that the glass shifted because the bond lacked strength. The replacement glass itself might have been fine, but the adhesive never reached full capability.

Notice the pattern. The bead is the root in each case.

Choosing the Right Partner for Auto Glass Replacement

You do not need to become a chemist to get a safe, quiet, and durable windshield. You do need to pick a shop that treats adhesives as critical, not incidental. Ask simple questions, and listen for confident, specific answers.

Here is a brief checklist that keeps the conversation focused:

- What adhesive system will you use on my car, and what is the safe drive-away time for today’s temperature and humidity? Will you apply both glass and pinchweld primers as needed, and how do you prep the surfaces? Do you document adhesive batch numbers on the invoice? How do you ensure bead height and windshield position, especially for vehicles with ADAS cameras? If conditions are too cold or wet, do you have a plan to control the environment or reschedule?

Those five answers reveal a shop’s standards more than windshield chip repair Carolina Beach any slogan.

Aftercare Matters More Than Most People Think

Once the windshield is in, your role is simple, but it matters. Avoid slamming doors for the first day, since cabin pressure can push against uncured sections and create microgaps. Leave the retention tape on as long as your installer recommends. Do not power wash the edges or run the car through a high-pressure tunnel wash until the adhesive has cured fully. If you have to drive over rough roads within the safe drive-away window, do it gently and avoid sudden chassis twists like angled driveway entries.

Pay attention to the first long highway drive. If you hear wind noise, call the shop quickly. A minor adjustment or reseal early can prevent a bigger fix later. The best shops prefer to catch small issues while the adhesive is still in a forgiving phase.

The Intersection of Speed and Safety

Mobile service has improved dramatically. With the right adhesive, proper prep, and environmental control, a technician can do an excellent auto glass replacement in your driveway. The trick is knowing when not to rush. There are days when the dew point and temperature make a 30-minute urethane behave like a two-hour product. A conscientious tech will tell you, and either adjust the plan or bring in supplemental heat and humidity. Shortcuts mostly save the installer time at the expense of your vehicle’s safety. A shop that refuses to cut those corners deserves your business.

What High-Quality Adhesives Look Like Over Time

A year after the job, the difference becomes clear. Quality adhesives keep their elasticity, hold the windshield tight against the body, and resist UV breakdown at the exposed edges. You do not see the bead crumbling like old tire sidewalls. You will not smell a musty cabin after storms. The car feels solid. That sense of solidity is not a placebo. You are feeling the body structure working as a single unit.

I once inspected a fleet of delivery vans that had windshields replaced by two different vendors. The first group, done with premium urethane and meticulous prep, had zero leaks and no wind noise at 70 mph after two years and more than 70,000 miles per van. The second group had about a 20 percent leak rate within a year, mostly at the lower edge near the cowl. The difference traced back to shortcuts in surface prep and a lower grade adhesive that did not hold up to daily heat cycles and torsional flex.

Where Windshield, Windshield Chip Repair, and Auto Glass Replacement Fit Together

A stray rock or a cold snap fracture can escalate quickly. If a chip appears, schedule windshield chip repair promptly. A good resin injection can leave you with a nearly invisible fill and prevent a full crack. If a replacement becomes necessary, treat the job as structural work, not glass decoration. Auto glass repair, whether chip repair or replacement, is about restoring integrity. The adhesive is the spine of that process.

Glass quality matters, but without an adhesive that bonds as designed, even the best windshield becomes a liability. Good shops know this. They choose urethanes that meet or exceed OEM standards, they stock the right primers, and they build real cure time into the schedule. They will also calibrate cameras if your car needs it, and they will test for leaks before handing you the keys.

The Bottom Line From the Bay

If I had to boil years of practice into one principle, it would be this: respect the bead. Treat the adhesive as the structural component it is. Clean everything that touches it. Use the complete system from a reputable manufacturer. Mind the clock. Control the environment. Insist on documentation. Do those things, and your windshield will do more than block the wind. It will support airbags, stiffen the body, keep rain where it belongs, and stay silent at speed.

When it comes to auto glass replacement, you can judge the work by three simple tests you can do yourself over the first weeks. Drive at highway speed with the radio off and listen. Wash the car and check for dampness or fogging near the pillars. Watch the ADAS indicators for random warnings or calibration prompts. If everything stays quiet and dry, and your driver assistance stays stable, your adhesive and your installer did their job. If not, bring it back and ask the questions that matter. Quality adhesives, applied with care, are not a luxury. They are the difference between a windshield that just sits there and one that truly protects.